Combined Flow Closed Cooling Tower

Key words:

Closed cooling tower, dry and wet combined cooling tower, open cooling tower

Classification:

- Product description

- Technical parameters

- Characteristics

-

ProcessprincipleTheheatedworkingfluidisflowinginsideofthecoil,whichisen-wrappedbyspraywaterontheoutside.Theheatofwaterisconductedbycoilandbecomethesaturatedvaporwhenmeetthewaterandair.Theheatisexhaust

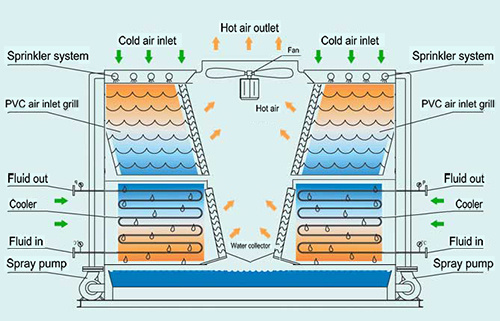

Process principleThe heated working fluid is flowing inside of the coil, which is en-wrapped by spray water on the outside. The heat of water is conducted by coil and become the saturated vapor when meet the water and air. The heat is exhausted out of the tower by the fan, and the water is collected back to the water tank for circulating. The spray water is cooled down when pass the PVC fills in the process of circulation, and flows in the same direction with the inlet cold air, and the coil mainly cooled by sensible heat conduction. So this type cooling tower is wildly used for high temperature cooling media.

Process principleThe heated working fluid is flowing inside of the coil, which is en-wrapped by spray water on the outside. The heat of water is conducted by coil and become the saturated vapor when meet the water and air. The heat is exhausted out of the tower by the fan, and the water is collected back to the water tank for circulating. The spray water is cooled down when pass the PVC fills in the process of circulation, and flows in the same direction with the inlet cold air, and the coil mainly cooled by sensible heat conduction. So this type cooling tower is wildly used for high temperature cooling media. -

Technical Parameters of Combined-flow closed type(single side into wind)

ModelCooling Capacity(K cal/h)

Flow Rate(m3/h)

Spray PumpFanPipe SizeDimensionWeight (approx)Power

(kw)Flow rate(m3/h)

Power

(kw)Qty.Inlet/

outletSupplySewageL*W*H (mm)Net weight(kg)Operating weight(kg)MSTNB-50

250000

50

1.5452.21DN80DN25DN252500*2300*3350

1650

3400MSTNB-65

325000652.2602.22DN80

DN25

DN25

3100*2300*3750

19004120MSTNB-80400 000

802.26032DN80

DN25

DN25

3400*2400*4200

26506200MSTNB-100500 0001002.211432DN100

DN25

DN25

3400*2400*4200

28206400MSTNB -125

625 000

1253.71404

2DN125

DN32

DN32

4000*3000*4250

34008800MSTNB -150

750 000

1503.71405.52DN150

DN32

DN32

4000*3000*4630

37509200MSTNB -175

875 0001755.51605.52DN200

DN40

DN40

4050*3000*4630

39509500MSTNB -200

1 000 000

2005.51605.53DN200

DN40

DN40

5810*3000*4630

452012900MSTNB -250

1 250 000

2505.51607.53DN200

DN40

DN40

5810*3000*4650

498013100Technical Parameters of Combined flow type(double sides into wind)

Notes:* Dates in the form is only for your reference, actual parameters should meet customers’ demands.* Design conditions: maximum flow rate ≤450m³/h, operating environment temp.≤31.5℃, wet bulb temp.≤28℃,humidity not higher than 85%,elevation below 1000m. (Taking antifreeze measures below 0℃)* Any queries for above parameters please contact our account executive. -

Characteristics

1. High cooling efficiencyCold air inlet from the top and side of the tower, heated exchanged from spray water, the cooling effect is better.2. Avoiding scalingThe cooling coils install up above the PVC fills, inlet cold air flows in the same direction with the spray water, so the spray water can complete cover the cooling coils and will avoid formation of dry point to form scale.3. Low noise, based on low revolving speed with wide leaf fan. Vulnerable parts using famous brand, low failure rate, cheap maintenance cost.4. High air duct design exhaust system to ensure ventilation quality, fast heat dissipation,ensure the cooling effect.5. Convenient maintenanceModular design is easy to assemble、disassemble and service.There is a maintenance passage inside tower, it is convenient for staff to entrance to examine and repair.6. Doouble sides into windThis model’s cooling capacity is more efficient. Cooling coils are layout in two sides, maximize the fan size. Enhance the air circulation.

Related Products

Product inquiry