Steel Open Water Cooling Tower

Key words:

Closed cooling tower, dry and wet combined cooling tower, open cooling tower

Classification:

- Product description

- Technical parameters

- Characteristics

-

MSTNKProcessprincipleWithoutcoolingcoils,theheatedworkingfluidbesprayedtothePVCfills,andreactswithcoldinletairforheattransferring,thentheheatisexhaustedoutofthetowerbythefan

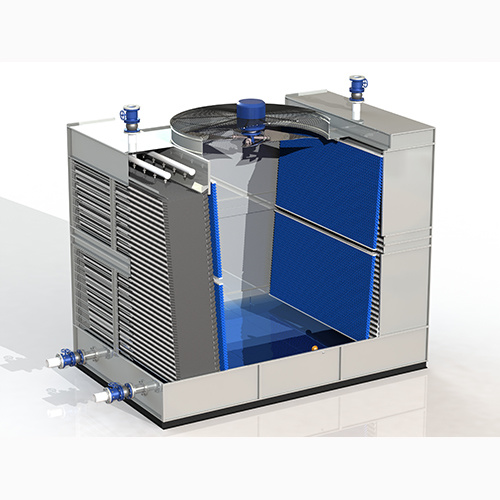

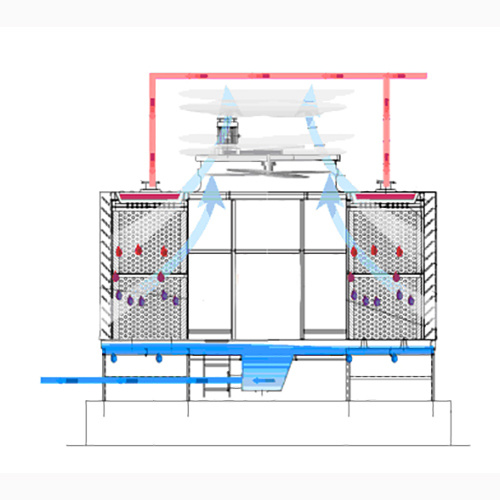

MSTNKProcess principleWithout cooling coils, the heated working fluid be sprayed to the PVC fills, and reacts with cold inlet air for heat transferring, then the heat is exhausted out of the tower by the fan, and the working fluid is collected back to the water tank for circulating.MSTHKrocess principleSimiary with MSTNK, but MSTHK model has two sides into wind, and the fan canister design to maximize. So that there has largest air flow space. Wide-chord hollow fan blade, reduce the nosie.

MSTNKProcess principleWithout cooling coils, the heated working fluid be sprayed to the PVC fills, and reacts with cold inlet air for heat transferring, then the heat is exhausted out of the tower by the fan, and the working fluid is collected back to the water tank for circulating.MSTHKrocess principleSimiary with MSTNK, but MSTHK model has two sides into wind, and the fan canister design to maximize. So that there has largest air flow space. Wide-chord hollow fan blade, reduce the nosie. -

Technical Parameters of Cross Flow Open type

ModelFlow Rate(m³/h)FanPipe Size(DN)Net weight(kg)Dimension(mm)PowerInlet OutletSewageSupplyMachine Size L*W*HFoundation sizeL*WMSTHK-10010041500100*2 1252525109039001980*3200*37002080*3300MSTHK-12512541800125*2 1503225135050502320*3600*37002420*3700MSTHK-1501505.52000125*2 1503225145059002600*3800*37002700*3900MSTHK-1751755.52000125*2 1503225150065602930*3800*37003030*3900MSTHK-2002007.52400150*2 2003225169076603040*4300*37003140*4400MSTHK-2252257.52400150*2 2003225190087502950*5080*41003050*5180MSTHK-2502507.52400150*2 2504040195092503000*5300*41003100*5400MSTHK-300300112800150*2 25040402350106003250*5550*41003350*5650MSTHK-350350112800150*2 25040402420117003500*5800*41003600*5900MSTHK-400400153000150*4 30040502730131503750*6050*42503850*6150MSTHK-450450153000150*4 30050502850145004000*6300*42504100*6400MSTHK-50050018.53000150*4 30050503250147504000*6300*48504100*6400Notes:* Dates in the form is only for your reference, actual parameters should meet customers’ demands.* Design conditions: maximum flow rate ≤450m³/h, operating environment temp.≤31.5℃, wet bulb temp.≤28℃,humidity not higher than 85%,elevation below 1000m. (Taking antifreeze measures below 0℃)* Any queries for above parameters please contact our account executive.Technical Parameters of Counter Flow Open typeModel

Flow Rate(m³/h)

Fan

Pipe Size(DN)

Net weight(kg)

Dimension(mm)

Power

(kw)Inlet

Outlet

Sewage

Supply

Machine SizeL*W*H

MSTNK-100

100

4

1800

125

125

25

25

1180

3300

2250*2250*4070

2350*2350

MSTNK-125

125

5.5

2000

150

150

32

25

1340

4015

2500*2500*4070

2600*2600

MSTNK-150

150

5.5

2000

150

150

32

25

1640

4870

2750*2750*4570

2850*2850

MSTNK-175

175

7.5

2400

150

150

32

25

1830

5720

3000*3000*4570

3100*3100

MSTNK-200

200

7.5

2400

200

200

32

25

2020

6630

3250*3250*4570

3350*3350

MSTNK-225

225

7.5

2400

200

200

32

25

2060

6800

3300*3300*4570

3400*3400

MSTNK-250

250

7.5

2400

200

200

40

40

2290

7650

3500*3500*4770

3600*3600

MSTNK-300

300

11

2800

250

250

40

40

2570

8750

3750*3750*4950

3850*3850

MSTNK-350

350

11

3000

250

250

40

40

2800

9860

4000*4000*4950

4100*4100

MSTNK-400

400

15

3300

300

300

40

50

3350

12350

4500*4500*5150

4600*4600

MSTNK-450

450

15

3300

300

300

50

50

3640

13900

4800*4800*5150

4900*4900

MSTNK-500

500

15

3600

300

300

50

50

4070

15000

5000*5000*5600

5100*5100

Notes:* Dates in the form is only for your reference, actual parameters should meet customers’ demands.* Design conditions: maximum flow rate ≤450m³/h, operating environment temp.≤31.5℃, wet bulb temp.≤28℃,humidity not higher than 85%,elevation below 1000m. (Taking antifreeze measures below 0℃)* Any queries for above parameters please contact our account executive.

-

Characteristics

1. Steel structure is more stabilizationThe tower out shell, water tank, support, exhaust air canister and other spare parts all are steel material. So the coolin towers have mechanical strength, good stability.2. CheaperRelative to closed cooling tower, there is no cooling coils inside, simple structure. So the price will be more cheaper.3. High-performanceRelative to FRP cooling tower, steel tower has stable structer, smooth operation, higher precision design standard, more secure performance indicators.4. Easy installation & maintainanceModular overall shipments, the lager models only need to connect the upper box and bottom box, it will reduce the installation difficulty and outerdoor operation cost.There is maintenance tunnel inside and large space, convinent to clean pvc fills and replace parts.5. Environmental protectionThere is no enviroment pollution risk of steel material. After reached the end of the service life, the steel material also could be recycle without secondary pollution.

Related Products

Product inquiry