FRP Water Cooling Tower

Key words:

Closed cooling tower, dry and wet combined cooling tower, open cooling tower

Classification:

- Product description

- Technical parameters

- Characteristics

-

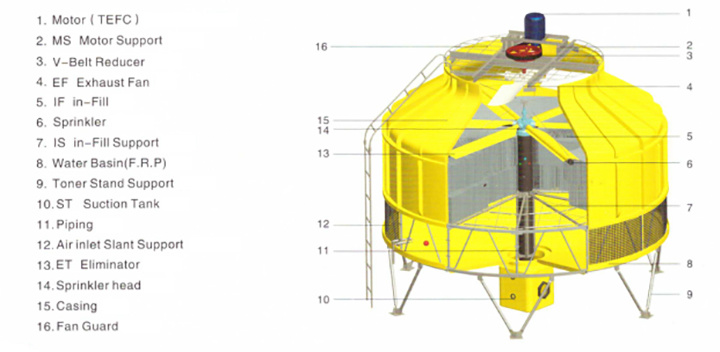

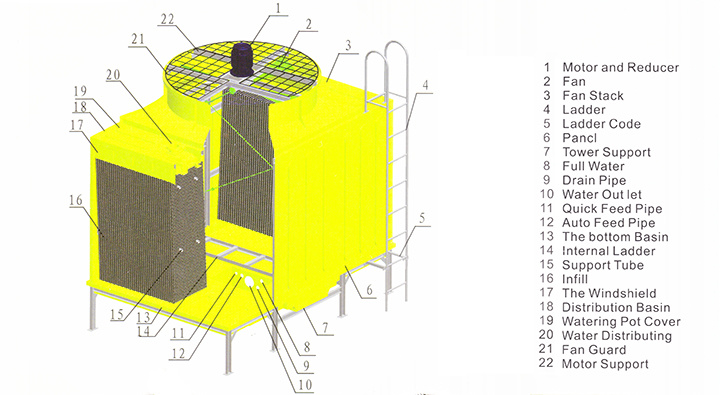

ProcessprincipleFRPoutshell.TheheatedworkingfluidbesprayedtothePVCfills,andreactswithcoldinletairforheattransferring,thentheheatisexhaustedoutofthetowerbythefan

Process principleFRP out shell. The heated working fluid be sprayed to the PVC fills, and reacts with cold inlet air for heat transferring, then the heat is exhausted out of the tower by the fan, and the working fluid is collected back to the water tank for circulating.

Process principleFRP out shell. The heated working fluid be sprayed to the PVC fills, and reacts with cold inlet air for heat transferring, then the heat is exhausted out of the tower by the fan, and the working fluid is collected back to the water tank for circulating. -

Technical Parameters of FPR Round Open type

Model

Flow Rate(m³/h)

Fan

Air flow(CMM)

Water Pressure(K pa)

Net weight(kg)

Operating weight(kg)

Dimension(mm)

Motor Power(kw)

D max

H

MSTBYK-10

7.8

0.18

Φ600

85

13

46

190

Φ945

1530

MSTBYK-15

11.7

0.37

Φ600

140

13

54

290

Φ1195

1415

MSTBYK-20

15.6

0.55

Φ730

160

14

67

300

Φ1195

1590

MSTBYK-25

19.5

0.75

Φ730

200

16

98

500

Φ1400

1820

MSTBYK-30

23.4

0.75

Φ730

230

16

116

530

Φ1650

1705

MSTBYK-40

31.2

1.5

Φ890

280

16

130

550

Φ1650

1775

MSTBYK-50

39.2

1.5

Φ890

330

17

190

975

Φ1830

1835

MSTBYK-60

46.8

1.5

Φ1150

420

17

240

1250

Φ2145

1955

MSTBYK-80

62.6

1.5

Φ1150

450

18

260

1280

Φ2145

2035

MSTBYK-100

78.1

2.2

Φ1410

700

21

500

1690

Φ2900

2370

MSTBYK-125

97.5

2.2

Φ1410

830

23

540

1640

Φ2900

2555

MSTBYK-150

117

2.2

Φ1410

950

23

580

1680

Φ2900

2555

MSTBYK-175

136.8

4

Φ1750

1150

30

860

1960

Φ3110

2850

MSTBYK-200

156.2

4

Φ1750

1250

30

880

1980

Φ3110

2850

MSTBYK-225

175.5

5.5

Φ2050

1500

33

1050

2770

Φ4120

3580

MSTBYK-250

195.1

5.5

Φ2050

1750

33

1080

2800

Φ4120

3580

MSTBYK-300

234

7.5

Φ2350

2000

34

1760

3930

Φ4730

3680

MSTBYK-350

273.2

7.5

Φ2350

2200

34

1800

3790

Φ4730

3680

MSTBYK-400

312.1

11

Φ2745

2400

36

2840

5740

Φ5600

3840

MSTBYK-500

392.4

15

Φ2745

2600

36

2900

5800

Φ5600

3840

MSTBYK-600

468

15

Φ3400

3750

42

3950

9350

Φ6600

4470

MSTBYK-700

547.2

18.5

Φ3400

3750

42

4050

9450

Φ6600

4470

MSTBYK-800

626.4

22

Φ3700

5000

45

4700

11900

Φ7600

4720

MSTBYK-1000

781.2

22

Φ3700

5400

45

4900

12100

Φ7600

4720

Technical Parameters of FRP Square Open type

ModelFlow Rate(m³/h)

Fan

Water Pressure(K pa)

Net weight(kg)

Operating weight(kg)

Dimension(mm)

Motor Power(kw*sets)

L

W

H

H1

H2

MSTHK-100B

100

2.2(4.0)*1

φ1500

36

860

2260

1980

3200

3700

2300

700

MSTHK-125B

125

3.0(4.0)*1

Φ1800

38

1080

2830

2320

3600

3700

2300

700

MSTHK-150B

150

4.0(5.5)*1

Φ2100

38

1180

3550

2600

3800

3700

2300

700

MSTHK-175B

175

4.0(5.5)*1

Φ2100

40

1300

3810

2930

3800

3700

2300

700

MSTHK-200B

200

5.5(7.5)*1

Φ2400

40

1600

4020

3040

4300

3700

2300

700

MSTHK-250B

250

3.0(4.0)*2

Φ1800

38

2050

5380

4640

3600

3700

2300

700

MSTHK-300B

300

4.0(5.5)*2

Φ2100

38

2240

6750

5200

3800

3700

2300

700

MSTHK-350B

350

4.0(5.5)*2

Φ2100

40

2470

7230

5860

3800

3700

2300

700

MSTHK-400B

400

5.5(7.5)*2

Φ2400

40

3040

7650

6080

4300

3700

2300

700

MSTHK-450B

450

4.0(5.5)*3

Φ2100

40

3360

9940

7800

3800

3700

2300

700

MSTHK-500B

500

3.0(4.0)*4

Φ1800

42

3580

10950

9280

3600

3700

2300

700

MSTHK-525B

525

4.0(5.5)*3

Φ2100

42

3710

11450

8790

3800

3700

2300

700

MSTHK-600B

600

5.5(7.5)*3

Φ2400

42

4560

12500

9120

4300

3700

2300

700

MSTHK-700B

700

4.0(5.5)*4

Φ2100

42

4940

15270

11720

3800

3700

2300

700

MSTHK-800B

800

5.5(7.5)*4

Φ2400

42

6080

18200

12160

4300

3700

2300

700

MSTHK-900B

900

4.0(5.5)*6

Φ2100

42

6730

19930

15600

3800

3700

2300

700

MSTHK-1000B

1000

5.5(7.5)*5

Φ2400

42

7600

22500

15200

4300

3700

2300

700

MSTHK-1200B

1200

5.5(7.5)*6

Φ2400

42

9210

22500

18240

4300

3700

2300

700

Notes:* Dates in the form is only for your reference, actual parameters should meet customers’ demands.

* Design conditions: maximum flow rate ≤450m³/h, operating environment temp.≤31.5℃, wet bulb temp.≤28℃,humidity not higher than 85%,elevation below 1000m. (Taking antifreeze measures below 0℃)* Any queries for above parameters please contact our account executive. -

Characterstics1.Compact StructureThere are no cooling coils inside the tower, so structure is compact, installation area is less.2. CheaperThe purchasing cost of equipment is much cheaper than steel type, but should notice the operating costs(water consumption, power consumption and etc).3. High quality FRPAgeing resistance, do not fade, anti-corrosion.

Related Products

Product inquiry