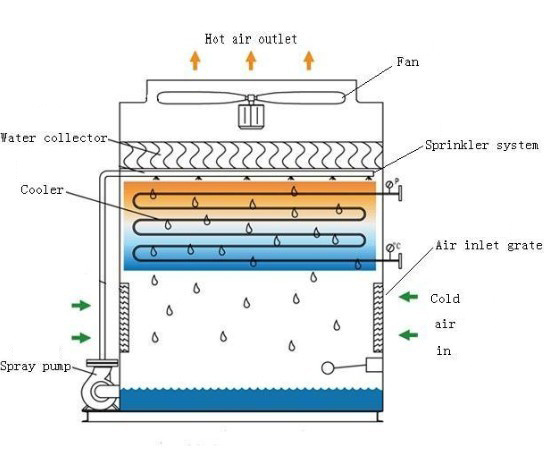

Counter Flow Closed Cooling Tower

ProcessprincipleTheheatedworkingfluidinletfromcoolingcoils,thenthewasteheatbetookawaybythefalldownspraywaterandreverseflowwiththecolddryairwhichisinletfromthebottomofthetowerandformtosaturatedvaporint

Key words:

Closed cooling tower, dry and wet combined cooling tower, open cooling tower

Classification:

- Product description

- Technical parameters

- Characteristics

-

ProcessprincipleTheheatedworkingfluidinletfromcoolingcoils,thenthewasteheatbetookawaybythefalldownspraywaterandreverseflowwiththecolddryairwhichisinletfromthebottomofthetowerandformtosaturatedvaporint

Process principleThe heated working fluid inlet from cooling coils, then the waste heat be took away by the fall down spray water and reverse flow with the cold dry air which is inlet from the bottom of the tower and form to saturated vapor in the process. The heat is exhausted out of tower by the top fan and the water is collected to bottom tank and circulate continuously by the special evaporator.

Process principleThe heated working fluid inlet from cooling coils, then the waste heat be took away by the fall down spray water and reverse flow with the cold dry air which is inlet from the bottom of the tower and form to saturated vapor in the process. The heat is exhausted out of tower by the top fan and the water is collected to bottom tank and circulate continuously by the special evaporator. -

Technical Parameters of Counter Flow Closed typeNotes:* Dates in the form is only for your reference, actual parameters should meet customers'demands.* Design conditions: maximum flow rate ≤350m³/h, operating environment temp≤31.5℃,wet bulb temp≤28℃,humidity not higher than 85%, elevation below 1000m.(Taking antifreeze measures below 0℃).* Any queries for above parameters please contact our account executive.

-

Characteristics1. Compact StructureCompare with other forms, there are no PVC fills inside, so this type’s structure is compact, installation area is less, meet the users’ space demanding.( We also could design the filled type according to customers’ requirement)2. High efficiencyFew cooling blind area, high thermal efficiency. High air duct design, make sure the equipment to meet the demand of cooling air flow rate in operation.3. Supporting auxiliariesWe can combine the tower with auxiliary together to be a whole suit, it will convenient for customers to operate, and easy to transportation & installation.

Related Products

Product inquiry