Cross Flow Closed Cooling Tower

ProcessprincipleTheheatedworkingfluidinletfromcoolingcoils,thenthewasteheatbetookawaybythefalldownspraywaterandcrossflowwiththecolddryairwhichisinletfromthesidesofthetowerandformtosaturatedvaporinthep

Key words:

Closed cooling tower, dry and wet combined cooling tower, open cooling tower

Classification:

- Product description

- Technical parameters

- Characteristics

-

ProcessprincipleTheheatedworkingfluidinletfromcoolingcoils,thenthewasteheatbetookawaybythefalldownspraywaterandcrossflowwiththecolddryairwhichisinletfromthesidesofthetowerandformtosaturatedvaporinthep

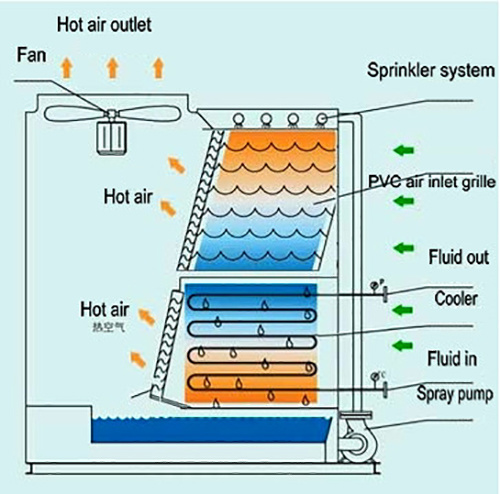

Process principleThe heated working fluid inlet from cooling coils,then the waste heat be took away by the fall down spray water and cross flow with the cold dry air which is inlet from the sides of the tower and form to saturated vapor in the process. The heat is exhausted out of tower by the top fan and the water is collected to bottom tank and circulate continuously by the special evaporator.Different from Counter Flow type, there are PVC fills inside.They per-cool the spray water, and flows in the vertical direction with cold water inlet, it will make more effective.

Process principleThe heated working fluid inlet from cooling coils,then the waste heat be took away by the fall down spray water and cross flow with the cold dry air which is inlet from the sides of the tower and form to saturated vapor in the process. The heat is exhausted out of tower by the top fan and the water is collected to bottom tank and circulate continuously by the special evaporator.Different from Counter Flow type, there are PVC fills inside.They per-cool the spray water, and flows in the vertical direction with cold water inlet, it will make more effective. -

Technical Parameters of Cross Flow Closed typeNotes:* Dates in the form is only for your reference, actual parameters should meet customers’ demands.* Design conditions: maximum flow rate ≤450m³/h, operating environment temp.≤31.5℃, wet bulb temp.≤28℃,humidity not higher than 85%,elevation below 1000m. (Taking antifreeze measures below 0℃)* Any queries for above parameters please contact our account executive.

-

Characteristics

1. Low noisePVC fills make high work efficiency and also can reduce the noisy of spray drops. Configure low noise fans.2. Avoiding scalingThe spray water’s temperature is lower than scaling temperature, smooth flow the cooling coil and the coils are damped completely, highly reduce scaling.3. Convenient MaintenanceModular design is easy to assemble, disassemble and maintenance.There is a maintenance passage inside the tower,and maintenance ladder, fence are equiped. They are convenient for staff to entrance to examine and repair.

Related Products

Product inquiry