Working principle of cooling tower:

Cooling tower is a kind of equipment that uses the contact of water and air to dissipate the waste heat generated in industry or refrigeration and air conditioning through evaporation. The basic principle is: after the dry (low enthalpy) air is pumped by the fan, it enters the cooling tower from the air inlet network; the high-temperature water molecules with high saturated steam pressure flow to the air with low pressure, and the damp heat (high enthalpy value) The water self-seeding water system is sprinkled into the tower. When water droplets are in contact with air, on the one hand, due to the direct heat transfer between air and water, on the other hand, due to the pressure difference between the surface of water vapor and the air, evaporation occurs under the action of pressure, which is the latent heat of evaporation. Take away the heat in the water, that is, evaporate and transfer heat, so as to achieve the purpose of cooling.

Working process of cooling tower:

Take the working process of the circular counterflow cooling tower as an example: the hot water autonomous machine room presses the circulating water into the water spreading system of the cooling tower through the pipeline, horizontal throat, curved throat and central throat at a certain pressure through the water pump, and evenly spreads the water on the packing through the small holes in the water spreading pipe; Dry air with low Han value enters the air network from the bottom into the tower under the action of the fan, when the hot water flows through the surface of the filler, a water film is formed to exchange heat with the air. The hot air with high humidity and high Han value is extracted from the top, and the cooling water drops into the bottom basin and flows into the main engine through the outlet pipe. Under normal circumstances, the air entering the tower is dry air with low wet bulb temperature. There is obviously a concentration difference of water molecules and a kinetic energy pressure difference between water and air. When the fan is running, under the action of static pressure in the tower, Water molecules continuously evaporate into the air and become water vapor molecules, and the average kinetic energy of the remaining water molecules will decrease, thus reducing the temperature of the circulating water. From the above analysis, it can be seen that the evaporative cooling has nothing to do with the temperature of the air (usually the dry bulb temperature) being lower or higher than the water temperature. As long as the water can continuously evaporate into the air, the water temperature will decrease. However, the evaporation of water into the air does not go on indefinitely. When the air in contact with water is not saturated, water molecules continue to evaporate into the air, but when the air on the water-gas contact surface is saturated, the water molecules cannot evaporate, but are in a state of dynamic balance. The number of water molecules evaporated is equal to the number of water molecules returned to the water from the air, and the water temperature remains unchanged. It can be seen that the drier the air in contact with the water, the easier the evaporation and the lower the water temperature.

Classification of cooling towers:

The 1. is divided into natural ventilation cooling tower, mechanical ventilation cooling tower and mixed ventilation cooling tower according to the ventilation mode.

According to the contact mode of hot water and air, the 2. is divided into wet cooling tower, dry cooling tower and dry and wet cooling tower.

According to the flow direction of hot water and air, the 3. is divided into counterflow cooling tower, cross flow (AC) cooling tower and mixed flow cooling tower.

4. according to the shape of the circular cooling tower, square cooling tower, rectangular cooling tower.

According to the cooling temperature, the 5. has standard cooling tower, medium temperature cooling tower and high temperature cooling tower.

6. according to the noise level is divided into ordinary type cooling tower, low noise type cooling tower, ultra low noise type cooling tower, ultra quiet type cooling tower.

According to the purpose of the 7. is divided into plastic machine special cooling tower, generator special cooling tower, medium frequency furnace special cooling tower, central air conditioning cooling tower, power plant cooling tower.

8. others have jet cooling towers, fan-free cooling towers, hyperbolic cooling towers, etc.

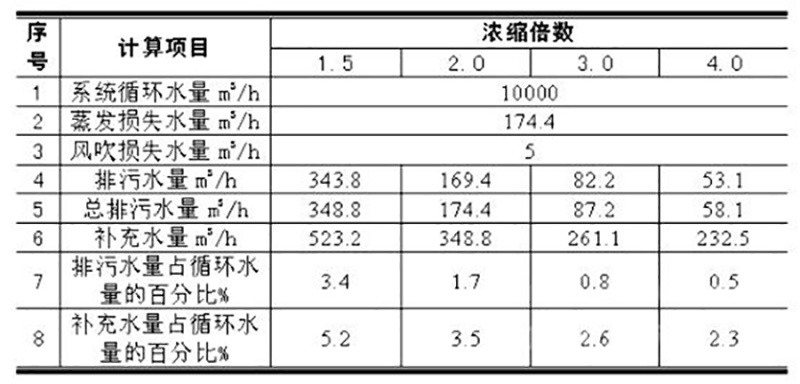

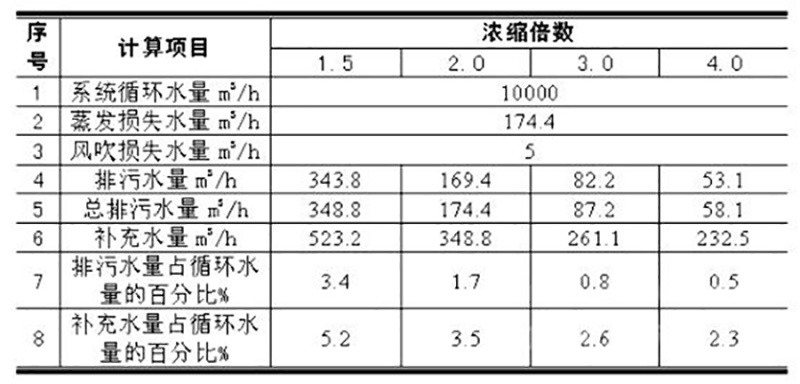

Replenishment of cooling water

Cooling tower water loss, including three parts: evaporation loss, wind loss and sewage loss, namely:

Qm = Qe Qw Qb where: Qm is the water loss of cooling tower; Qe is the water loss of Yanfa; Qw is the loss of wind blowing; Qb is the loss of sewage water.

(1) Evaporation loss

Qe= (0.001 0.00002i) Δt Q1

Where: Qe is the amount of evaporation loss; Δt is the temperature difference between the cooling tower and the water; Q is the amount of circulating water; θ is the dry bulb temperature of the air.

(2) Water loss by wind

For mechanical draft cooling towers with water eliminators, the amount of wind loss is

Qw=(0.2%~0.3%)Q (2)

(3) Blowdown and leakage loss

This loss is a relatively mobile item, which is related to the requirements of circulating cooling water quality, treatment methods, the quality of supplementary water and the concentration multiple of circulating water. the formula for the calculation of the concentration multiple:

N =Cr/Cm

In the formula: N is the concentration multiple; Cr is the salt content of circulating cooling water; Cm is the salt content of supplementary water.

According to the salt content balance of the circulating cooling water system, the salt content brought into the system by make-up water should be equal to the salt content taken away by blowdown, wind blowing and seepage deviation..

According to the salt content balance of the circulating cooling water system, the salt content brought into the system by the make-up water should be equal to the salt content taken away by sewage, wind and seepage.

QmCm= (Qw Qb)Cr

N = cr/cm = qm/ (QW QB) = (QE QW QB)/(QW QB) (3)

Qm= QeN/(N 一1)

The concentration multiple is the ratio of the salt content of the supplementary water to the salt content of the concentrated cooling water. The N value recommend the Building Water Supply and Drainage Design Manual is generally not more than 5-6. If the N value is too large, the sewage and leakage losses will inevitably cause water waste. If the N value is too small, the water replenishment amount is small, and the cooling water concentration is large, it will cause dirt and corrosion of the system.

The amount of evaporated water can be calculated by formula (1), then the amount of water lost by wind (2), and finally the amount of water lost by sewage and leakage can be calculated by formula (3).

Example: cooling engine cooling water circulation 570M3/h, using the starting circular counterflow cooling tower cooling system.

Loss of cooling tower:

1, evaporation loss of water: initially determine the supplementary water cooling tower, can be calculated as follows

QE =(0.001 00002x) T q = ktq

Qe --- water loss due to evaporation; T --- temperature difference between cooling tower and inlet water; Q --- circulating water volume; X --- wet bulb temperature of external air (28.6 degrees)

2. Water loss by blowing: (0.2~0.3) Q = Qw

3. Water loss from sewage discharge: Qb

Total water replenishment: Qm = Qe Qw Qb Qm = Qe ×N/(N-1)

Concentration multiple: N = 3

QM =(0.001 + 0.00002 × 28.6)× 5 q× 3/(3-1)= 0.012q = 1.2% q = 6.8m 3 。

How to determine the concentration multiple? (generally 3-6)